This blog is your go-to guide for everything related to your warehouse management. From handling incoming goods with care to making sure they’re stored, managed, and shipped out efficiently, you’ll learn to optimize your most important workflows.

You’ll dive into how blending old-school methods with the latest automation technology:

- Cranks up your warehouse’s operational efficiency.

- Cuts down on costs.

- Keeps your team safe and sound.

To reach peak warehouse efficiency, you’ll learn:

- The critical role of warehouse operations.

- The tangible benefits of refining warehouse processes.

- Practical tips for optimizing your warehouse, including automation.

Let’s get started!

What are warehouse operations?

Warehouse operations involve the different tasks you do in a warehouse to ensure the safe storage and transfer of your goods. The main processes in warehouse management include:

- Receiving goods.

- Item storage.

- Inventory management.

- Packing and shipping.

How to operate a warehouse

You can perform warehouse tasks manually or with the help of machines. For example, using a paper list to pick items for orders is a manual way of doing things. On the other hand, using a handheld GPS device to guide a worker to the right location is an example of automation.

These days, warehouses use both manual and automated methods to get work done. But, there’s a growing trend towards automation to increase fulfillment speed and efficiency.

The pivotal role of warehouse operations

Warehouse operations serve as the backbone of the supply chain. They play a pivotal role in ensuring the smooth and efficient flow of goods from suppliers to customers. This critical function directly impacts a company’s ability to:

- Meet customer demands.

- Manage inventory levels.

- Control operational costs.

Why focus on improving warehouse operations?

Cost control

Efficient warehouse management is key to controlling operational expenses. You save significantly when you simplify:

- Inventory management.

- Order processing.

- Shipping.

This is because you’re able to cut down on waste and improve resource allocation. So, you:

- Spend less on labor.

- Reduce the costs of storing inventory.

- Minimize losses from damaged goods.

Protect employees and stay safety compliant

Improving warehouse functioning also means putting the safety and health of your employees first. You reduce the risk of accidents and injuries through:

- Solid safety measures.

- Thorough training.

- Proper equipment.

You also create a positive workplace atmosphere, which boosts employee morale and productivity.

Maximize the space you have

Optimizing warehouse effectiveness includes making smart use of available warehouse space. Through careful planning of your layout and the right storage solutions, it’s possible to increase your storage capacity and simplify operations.

More space means more inventory and a better flow of goods. As a result, you speed up processing times and boost order fulfillment rates.

Error-proof your asset inspection process

Error-proofing your asset inspection process is crucial for inventory accuracy. By setting up inspection routines and using technology to track and monitor inventory, you can reduce mistakes in stock counts. This ensures fewer discrepancies and more accurate order fulfillment.

Overall, you save on the costs associated with fixing errors and keep your supply chain running smoothly.

Your growth and bottom line

At the end of the day, improving warehouse management has a direct impact on your growth and financial health. Efficient operations mean you can:

- Quickly adapt to market changes.

- Scale up or down as needed.

- Keep customers happy.

By cutting costs and boosting productivity, you increase your competitive edge and profitability. As a result, you pave the way for sustainable growth.

How to optimize warehouse operations

1. Train employees

Empower your team with the knowledge and skills they need to perform well. Regular training sessions on the latest warehouse management practices and technologies ensure that employees are efficient, productive, and capable of maintaining high standards.

2. Regularly review your warehouse efficiency by implementing KPIs

Keep a close eye on your warehouse’s performance by setting and tracking key performance indicators (KPIs). You can identify areas for improvement by regularly reviewing metrics like:

- Order accuracy.

- Inventory turnover.

- The time it takes to ship products.

By understanding your warehouse’s strengths and weaknesses, you’ll make informed decisions to enhance efficiency.

3. Organize your inventory and warehouse setup

A well-organized warehouse is an efficient one. Optimize your warehouse layout to ensure that your frequently used items are easily accessible and that the flow from receiving to shipping is direct.

Similarly, keep your inventory organized to reduce the time you spend locating items. This speeds up the order fulfillment process and improves your bottom line.

4. Start automating your workflows

Automation is one of the best ways to simplify your warehousing. From inventory management systems to automated packing processes, technology can:

- Reduce manual labor.

- Minimize errors.

- Increase the speed of operations.

Overall, automation boosts efficiency and lets your team focus on more strategic tasks that require human insight.

How does warehouse operation automation work?

Lead-to-cash automation for QuickBooks and Xero users

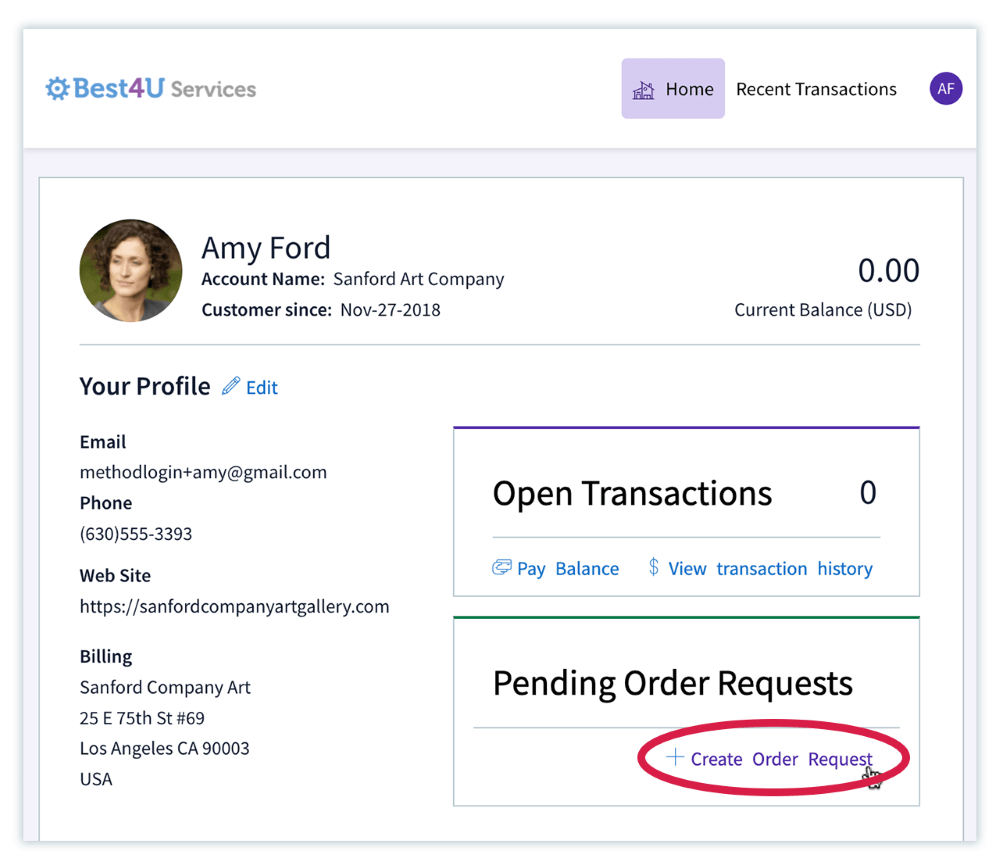

If you’re a manufacturer using QuickBooks or Xero, lead-to-cash automation offers a comprehensive solution for end-to-end back office automation. Method provides a seamless connection with your accounting platforms to give you an all-in-one solution that covers every aspect of the sales process, from initial lead capture to service and final payment.

This integration simplifies your operations by automating tasks like:

- Order processing.

- Inventory management.

- Invoicing.

- Payment collection.

With Method, you gain a holistic view of your financials and customer interactions. As a result, you:

- Enhance efficiency.

- Reduce manual entry errors.

- Improve customer satisfaction.

Benefits of improving warehouse operations

Improving warehouse management simplifies your supply chain and brings advantages that greatly impact your business’ efficiency and customer satisfaction.

Reduce errors in inventory management

By enhancing warehouse management, you reduce errors in inventory management. Accurate inventory tracking and management prevent overstocking and inventory shortages, so your resources are allocated optimally. With better forecasting, planning, and fulfillment processes, you save costs and reduce waste.

Maximize picking accuracy

Improving warehouse functions also contributes to picking accuracy. Implementing systems like barcode scanning and real-time inventory updates reduces picking errors, so your customers receive the correct items every time. This efficiency minimizes returns and exchanges while you simplify your order fulfillment process.

Ship orders faster

Another key benefit of optimizing warehouse management is the ability to ship orders faster. Warehouse practices like optimized layout designs and automated picking systems speed up the order fulfillment process.

And with faster shipping times, you improve customer satisfaction and gain a competitive edge.

Improve customer satisfaction

Efficient warehouse management ensures that:

- Products are in stock.

- Orders are accurate.

- Shipments arrive on time.

This reliability builds trust with your customers, which leads to repeat business, positive reviews, and a strong brand reputation.

In the long run, satisfied customers are the cornerstone of a successful business, which makes optimizing your warehouse management a critical strategy for growth.

What warehouse processes and workflows can be automated?

Here’s a look at key warehouse operations that benefit from automation:

Receiving goods

You can automate the process of checking, documenting, and sorting inventory as it arrives. Automated systems can:

- Scan barcodes.

- Verify shipments against purchase orders.

- Update inventory levels in real time.

As a result, you guarantee inventory accuracy from the outset.

Warehouse storage

Automated storage systems can also assign locations for goods based on size, weight, and frequency of access. As a result, you improve the way you use space and reduce retrieval times.

Robotics and automated guided vehicles (AGVs) can also transport goods to their designated locations, which reduces manual work.

Picking, packing, and shipping

Automation technologies can accelerate your picking, packing, and shipping processes. These systems include:

- Robotic pickers.

- Automated sorting systems.

- Conveyor belts.

When you leverage this technology, you reduce the time it takes to:

- Gather items for an order.

- Package them securely.

- Prepare them for shipment.

Ordering and reordering goods

Automated inventory management systems play a vital role in maintaining optimal stock levels. They can predict when stock will run low and automatically initiate reorder processes.

Method’s repeat purchase feature simplifies warehouse management. With this update, your customers can easily request reorders directly from their customer portals with just one click, which simplifies the process of ordering and reordering goods.

This automation reduces potential errors and enhances customer satisfaction. Additionally, it offers valuable insights into purchasing behaviors to improve inventory management.

Wrap-up: How to optimize warehouse operations

Optimizing warehouse management is vital to:

- Enhance supply chain efficiency.

- Reduce costs.

- Improve customer satisfaction.

Namely, you can greatly simplify your processes with strategies like:

- Training.

- KPI implementation.

- Inventory organization.

- Automation.

Automation, in particular, offers huge benefits like accuracy and speed across all your warehouse functions.

Method’s powerful combination with your QuickBooks or Xero software ensures that you can focus on growth and innovation knowing your back office operations are taken care of.

Improving warehouse operations FAQs

What are the key work activities in warehouse operations?

The key activities in warehousing include:

- Receiving goods.

- Storing items efficiently.

- Managing inventory accurately.

- Picking and packing orders.

- Shipping them out.

These activities ensure that your warehouse operates smoothly and you fulfill orders promptly.

What is warehouse management?

Warehouse management involves overseeing a warehouse’s operations on a day-to-day basis. This includes things like:

- Managing inventory levels.

- Optimizing storage space.

- Ensuring efficient order processing.

- Maintaining a safe and productive work environment.

What is a warehouse management system?

A warehouse management system (WMS) is a software solution that supports and optimizes warehouse functionality and distribution center management.

It facilitates entire warehouse management processes from inventory entry to order fulfillment by offering tools for:

- Inventory management.

- Picking processes.

- Auditing.

- Reporting.

See how Method improves warehouse operations.

Image credit: BGStock72 via Adobe Stock